Uni-Mod: Universal Modular Engine

The Uni-Mod is a universal opposed piston, two-cycle, "crankless" engine, comprised of 2 combustion chambers with 2 pistons per chamber. Internal combustions impact against a lever arm extracting as much energy as possible. This mechanical energy is directly converted into fluid power. During engine operation all moving parts on one side of the front and rear fulcrums move simultaneously away from each other as all moving parts on the opposite side move towards each other. This provides a perfectly balanced combustion sequence.

A built in super-charger provides air input and unlike most 2-cycles the Uni-Mod engine has what we call “perfect scavenging”. Input air-fuel mixtures are forced up against the exhaust gases in a manner that does not allow the new air-fuel mixture to go out the exhaust ports. The Uni-Mod operates at a constant speed and does not idle. This maximizes overall efficiency and keeps the air-fuel mixture controlled, reducing harmful emissions. Our current Uni-Mod design is sized to produce roughly 40 HP.

Modularity

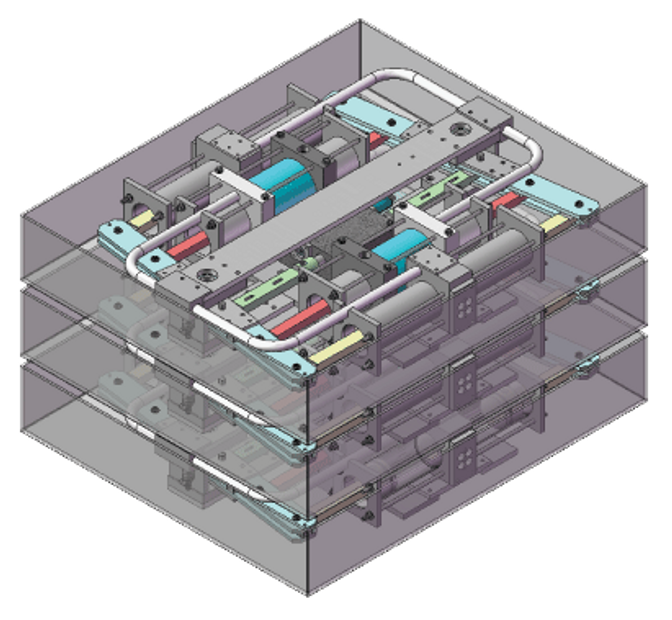

All components and operating fluids that make up a Uni-Mod engine are contained in standard shaped modular cases. Modules are plugged into "hydraulic bus-bars". A Uni-Mod operates solo or in parallel with as many modules needed. A Uni-Mod module can be easily swapped out of a system for service. This significantly reduces down time and makes for a very "mechanic friendly" machine.

A Truly Service Friendly Engine

Limited Down Time and Superior Reliability

As seasoned mechanics designing the Uni-Mod to be easily serviced has been a top priority. No need for head gaskets, camshafts, tulip valves or complex gear sets.

A complete Uni-Mod engine module is designed to be swapped out in a matter of minutes.

Uni-Mod and Crankshaft Engine Comparison

Uni-Mod Variable Stroke Engine

Uni-Mod Variable Stroke Engine

Crankshaft Fixed Stroke Engine

Testing

Breaking in Prototype-7.

Hands on Controls.